June 25, 2020 14:7

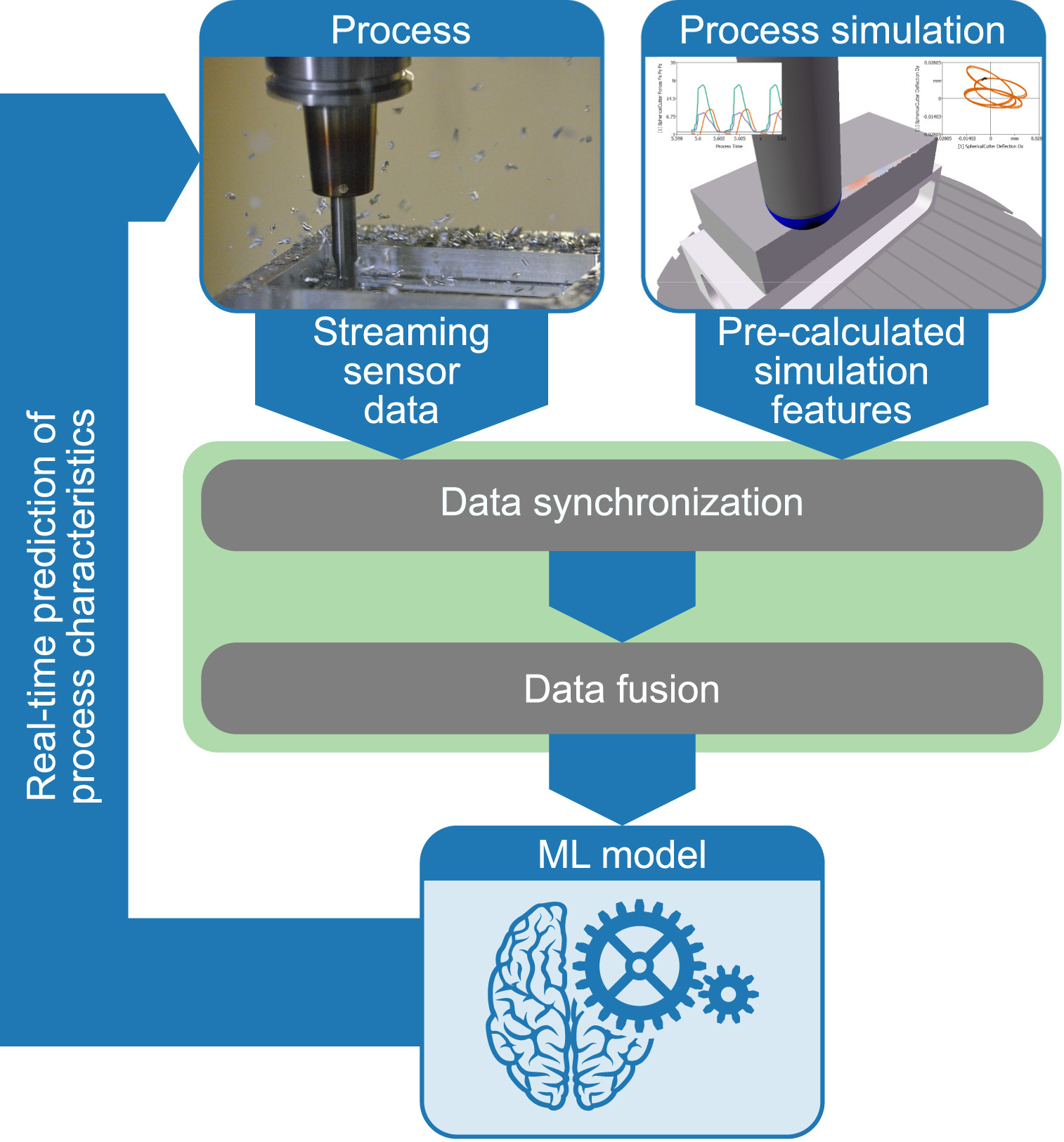

We are happy to announce that the newest article of project B3 "Real-time prediction of process forces in milling operations using synchronized data fusion of simulation and sensor data" is now available at ScienceDirect (follow: this link) for free access until August, 9th.

The paper focuses on Machine Learning based predictions in milling processes. In mechanical engineering, milling is one of the most important machining operations with a wide variety of application use cases, e.g., the machining of structural components for the aerospace industry, dental prostheses or forming tools in the context of the tool and die manufacturing. Different challenges arise for different process strategies, milling tools and machine tools, such as tool vibrations of long and slender finishing tools causing chatter marks on the workpiece surface and tool wear for long-running processes.

Nowadays, in the context of Industry 4.0, Machine Learning methods have allowed production processes, including machining, to be better understood and intelligently transformed. Data gathered and evaluated during these processes is the fundamental basis of such transformation. The industrial processes can thus not only be better understood, but also optimized.

In this context, to prevent undesirable effects during milling processes, the paper proposes a novel approach for combining simulation data with sensor data to generate online predictions of process forces, which are influenced by tool wear, using an ensemble-based machine learning method. In addition, a methodology was developed in order to synchronize pre-calculated simulation data and streaming sensor measurements in real time. Sensor data was acquired using milling machines by the Virtual Machining group of the Chair for Software Engineering in the laboratories of the Institute of Machining Technology (ISF), TU Dortmund. The geometric physically-based simulation system has also been developed in the same chair.